Alyeska Sustainability Report illustrates best of 2023

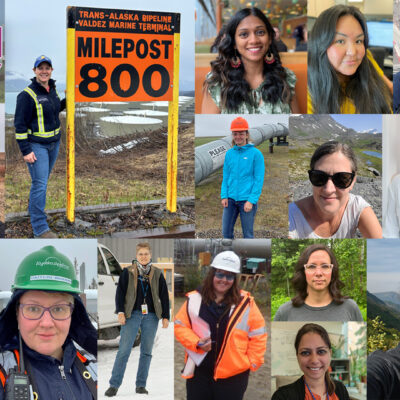

Alyeska published its 2023 Sustainability Report, highlighting its dedication to environmental stewardship, sustainable practices, and safe operations of TAPS, as well as spotlighting staff, their work and community connections.